Container movements involve multiple handovers between operators and carriers. Each transfer introduces risk where access can occur outside agreed processes. The ability to confirm whether a container has been opened since the last checkpoint supports informed inspection and decision-making at delivery.

In freight and logistics operations, seals applied to container doors provide a reference point for checking access during transit. Their value comes from how they are checked and inspected at each stage, not from acting as a physical barrier alone.

What Are Container Security Seals?

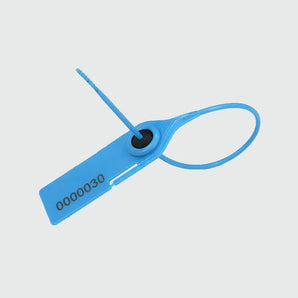

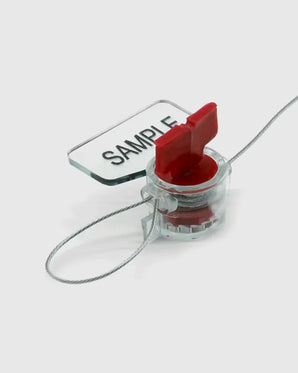

These devices are fitted to container door locking points. They show if access has taken place or been attempted after the seals have been applied. They are selected to match the container and the conditions in which they’re handled.

Applied correctly, seals give receiving teams a clear reference for inspection. The presence of an intact seal supports confirmation that the container doors have not been opened since the last recorded handover.

How do Seals Deter Theft During Container Transit?

Seals do not physically stop access to a container, but their deterrent effect comes from the expectation of inspection and record checks at delivery points.

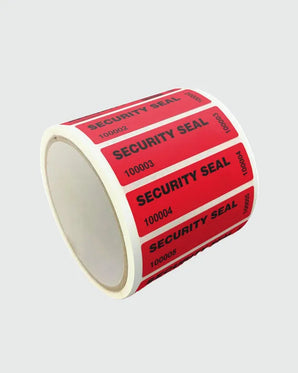

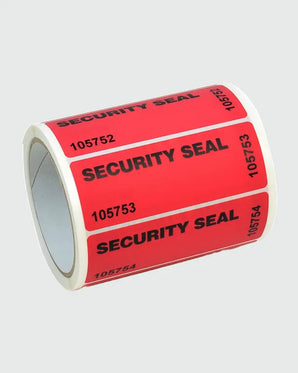

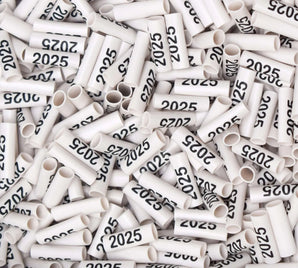

Accountability in security seals is created by linking a seal number to paperwork. Where inspection processes are active, interference becomes easier to identify and escalate. This reduces casual access during transit because altered seals attract attention during checks.

What Types of Seals Are Used on Shipping Containers?

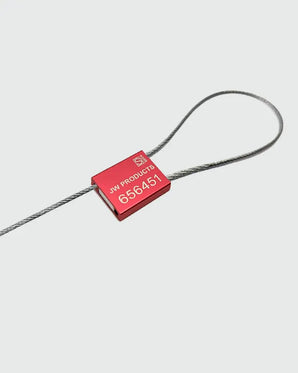

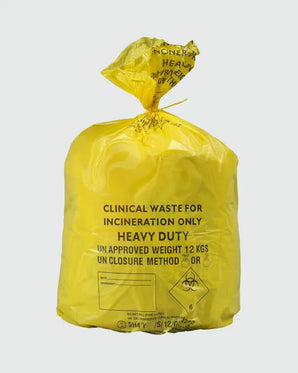

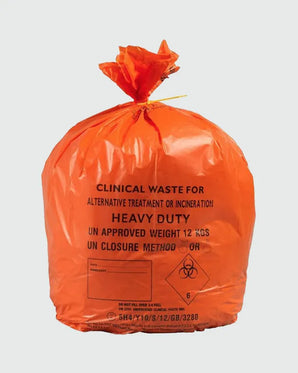

Several formats are used for shipping container security seals, each designed for container doors. Common options include indicative seals and bolt seals.

A comparison that’s often made over tamper evidence is container seals vs bolt seals. Bolt seals are widely used on freight containers because they meet ISO 17712 requirements for high security applications. Indicative seals may be used where monitoring access is the primary concern.

Selection should also take account of container type and door configuration. Standard ISO containers and refrigerated containers use different locking hardware, which can affect how the seal fits. The length of the seal, its diameter, and the locking mechanism all influence how easily a seal can be applied and checked during handling. Choosing a seal that suits the specific container design helps avoid ambiguity.

What Does ISO 17712 Mean For Container Sealing?

ISO 17712 high security seals for containers sets performance and testing criteria for seals used on freight containers. Certification relates to seal strength and testing standards.

Using a ISO 17712 compliant seal supports supply chain security programmes and customs procedures. The standard does not remove the need for inspection. Seal condition and number checks still need to take place at each handover.

During international shipments, a seal’s condition is commonly reviewed as part of border and customs checks. A missing, broken, or mismatched seal can lead to delays while the cause is investigated.

How Should Seal Numbers be Checked at Handover?

Checking container seal numbers against paperwork is central to inspection routines when the container is being handed over. The seal number applied at dispatch should match the number recorded on transport documents and digital tracking systems.

Inspection should take place before the container is moved or opened. The seal number should be read directly from the body of the seal and compared with the recorded reference.

Where discrepancies are found, procedures should require escalation before the container is unloaded. This prevents assumptions being made about access and ensures that potential interference is addressed through the correct operational process.

What Tampering Methods Are Common on Container Seals?

Common tampering methods seen on container seals include cutting seals or using counterfeit seals that mimic genuine products. These approaches aim to allow access while attempting to avoid detection during routine checks.

Use of security seals introduces an inspection reference that makes these actions easier to detect. Recognition of common tampering patterns helps inspectors identify irregularities such as an inconsistent seal appearance or unexpected damage.

Not all broken seals indicate deliberate interference. Accidental damage can occur during loading or shunting if seals are poorly applied or exposed to contact with equipment. Inspection procedures typically treat any damaged seal in the same way initially, ensuring that access is investigated before assumptions are made about intent.

Training and clear procedures increase the likelihood that interference is identified during delivery checks.

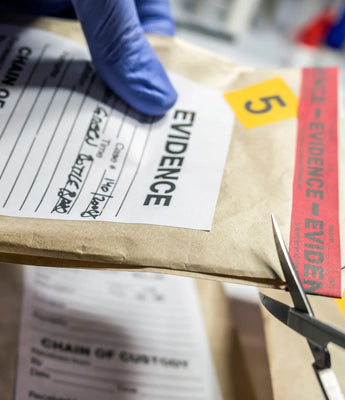

How Can Tampered Seals be Identified at Delivery?

Careful inspection is required to identify tampered security seals at delivery. Inspection should focus on seal integrity and consistency with the seal type that was recorded at dispatch.

Checks should include confirming that the seal number matches the paperwork, assessing whether the seal body shows signs of cutting or distortion, and verifying that the seal design matches expected formats.

Inspection should always occur before container doors are opened.

How Should Seal Information be Recorded at Each Handover?

A consistent recording process at each transfer point supports chain of custody requirements for security seals. Seal numbers should be logged at application and receipt.

Best practices for security seals include:

- Recording seal numbers accurately at dispatch

- Verifying seal condition during transit checks

- Confirming seal numbers before unloading

Clear records support accountability across freight movements.

How Are Seals Applied to Containers Correctly?

Correct application begins with selecting a seal suited to the container door locking points. The seal should pass cleanly through the designated hasp or latch without forcing or modification.

Application should follow manufacturer guidance to ensure the seal closes fully and locks as intended. Partial engagement or misalignment can create ambiguity during inspection.

Once applied, the seal number should be recorded immediately and the seal visually checked to confirm it is secure. Consistent application supports reliable inspection outcomes during transit and delivery.

Where Are Seals Used Across UK Freight Operations?

Across UK freight and logistics operations, security seals appear at ports and inland depots where containers enter or leave controlled environments. They are also used during onward movement through distribution centres and bonded facilities where responsibility transfers between parties.

Using them at these points supports inspection protocols before containers move on to the next stage of transport. Checking seals provides a reference for confirming that container doors have not been opened between locations.

Doing this across routes helps standardise checks and reduces uncertainty during handovers, particularly where multiple carriers or storage locations are involved.

What Triggers Changes in Container Sealing Processes?

Reviewing sealing procedures is appropriate when routes change or inspection issues are identified. Changes in container type or operating conditions may also require reassessment.

Organisations reviewing container security processes may benefit from discussing product options and application guidance. We supply a range of security seals suited to freight and logistics environments.

To discuss seal types, and your specific requirements, contact us for practical guidance based on how your containers are handled and inspected.