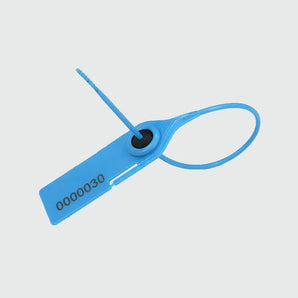

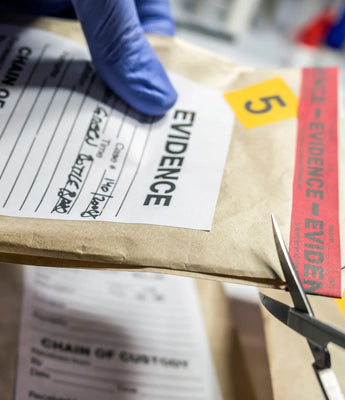

These labels are used across a wide range of operational environments where controlled access is part of an established process. They appear on containers where visibility of interference matters to the organisation applying them. These products support inspection routines without acting as barriers or protective devices.

Within logistics and healthcare, labels that show evidence of access help teams verify whether an item has been opened since it was last checked. An understanding of what these products do and how they function helps organisations decide where they fit within their own handling procedures.

What Shows That a Label Has Been Interfered With?

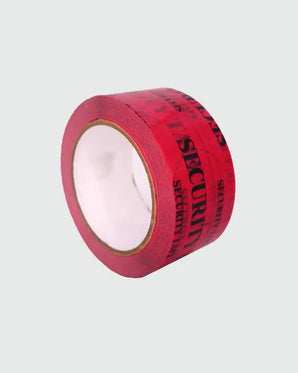

These labels are engineered to provide evidence if they’ve been removed, or if it looks like their removal has been attempted after they’ve been applied. The interaction between the label and the surface determines how that evidence appears.

Examples include labels that fragment on removal or labels that distort permanently once lifted. Each format supports inspection by making interference clear to anyone checking the item.

Used in this way, the labels do not restrict access or stop handling. The focus stays on inspection.

What Separates Tamper Evident Labels From Standard Adhesive Labels?

Standard labels prioritise adhesion but tamper evident versions prioritise giving evidence that interference has occurred.

These use materials and adhesives selected to react when removal is attempted. That reaction creates a visible indicator that handling has taken place, supporting inspection without implying protection or prevention.

The benefits of tamper evident security labels relate to process definition. They make unauthorised access easier to identify during checks. Effectiveness is shaped by correct placement, surface preparation, and staff awareness.

How do Void Security Labels Show Signs of Removal?

These labels reveal a pre-set word or pattern when removal occurs. The message stays apparent on the surface of whatever material it’s been adhered to.

Inspection becomes straightforward because the altered state contrasts clearly with an intact label. Void formats are used where quick visual confirmation matters, including asset tracking. The message itself does not carry authority or enforcement. It indicates that it has been opened.

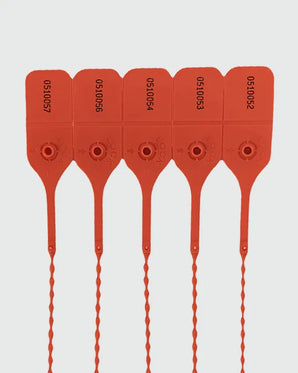

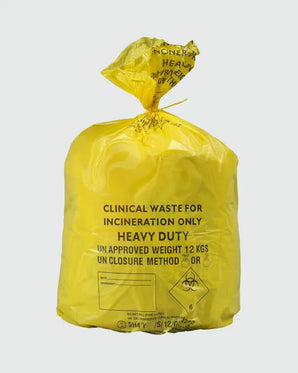

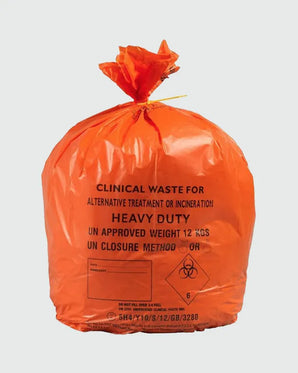

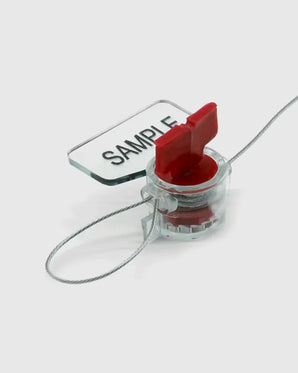

Where Are Labels Applied Within Supply Chain Handling?

Security label uses in supply chain operations focus on transfer points. Labels appear on cartons and containers moving between locations or teams. The purpose is to support handover checks.

Typical applications include sealing outer packaging and marking inspection points. Security labels in these contexts assist with confirming whether handling occurred between checkpoints. Staff must follow inspection steps built into the process.

How Are Labels Used Across Logistics and Transport Workflows?

In logistics and transport, security labels appear during transit activities. They help teams confirm whether access occurred between dispatch and receipt, including vehicle documentation and sealed containers. Labels provide a clear reference during arrival checks.

How Labels Are Used for Asset Identification?

For asset protection, security labels focus on identification without acting as a defensive measure. Applied to equipment, they show whether an item has been opened or adjusted since the last inspection.

Asset registers gain value when inspection results are recorded with the label’s condition. The label supports the process by making interference visible. Whoever is managing the asset is then responsible to respond accordingly.

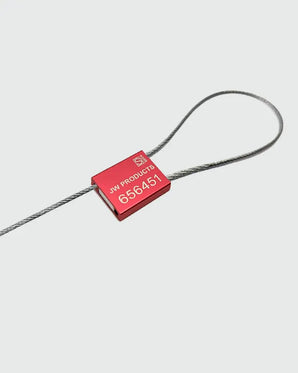

What Factors Influence Selection for Different Environments?

Choosing security labels requires careful assessment of the environment in which they will be applied and inspected. Surface material is a primary consideration because adhesive performance varies significantly between smooth plastics and coated metals. Labels must bond consistently without premature lifting or surface damage during removal.

Environmental exposure also affects suitability. Temperature range and cleaning routines can influence adhesive behaviour and material stability. Labels used in refrigerated storage or outdoor locations require different specifications from those used in dry, controlled interiors.

Inspection frequency and handling intensity should inform selection. Labels checked multiple times a day or applied to items that are moved repeatedly need clear visual indicators that remain legible throughout the inspection cycle. Selection should reflect operational conditions and avoid assumptions about protection or control.

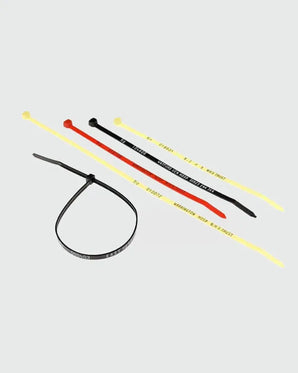

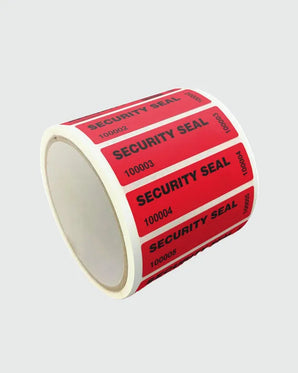

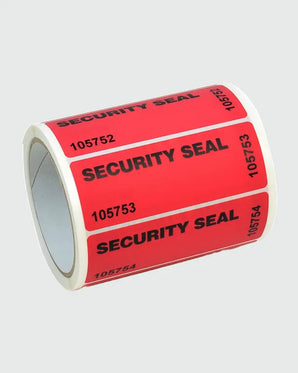

When is Custom Specification Required?

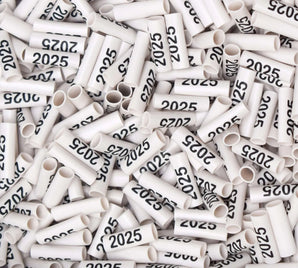

UK supply options for custom security labels allow organisations to specify numbering. This approach supports internal identification and process alignment.

Typical custom features include sequential numbering or logos. These additions help teams recognise correct placement and identify items during checks. The underlying function of the label does not change. It still functions as an indicator of interference only.

Where Can Organisations Source Labels Suited to Their Processes?

The question of where to buy security labels is influenced by specification requirements and supply continuity. Manufacturers and suppliers with product-led experience can explain how different materials behave across surfaces and environments, helping organisations avoid unsuitable selections.

Reliable sourcing also involves consistency. Batch variation or discontinuation can undermine established inspection processes. Organisations benefit from suppliers that maintain stable product ranges and provide clear documentation.

Suppliers provide labels to specification and advise on availability. Responsibility for application then sits with the user.

How Should Labels be Integrated Into Inspection Routines?

Effective use of security labels relies on documented procedures. Staff need to know:

· Define inspection points within the process

· Train staff on recognising altered labels

· Record findings consistently

Integration ensures that labels contribute useful information without creating false assumptions about control.

What Practical Limits Should Organisations Understand?

Security labels function as indicators only. They do not prevent access or secure contents. Their value comes from making interference visible.

Labels should never be treated as substitutes for procedural controls or staff oversight. Misinterpretation can lead to misplaced confidence or inconsistent inspection practices.

Clear internal guidance on what labels can and cannot indicate helps ensure they support operational checks without overstating their purpose or creating assumptions about security.

When Should Organisations Review Their Use of Security Labels?

These products provide evidence of interference that supports inspection. Effectiveness is shaped by the correct selection, application, and integration into existing procedures.

Organisations reviewing current processes or planning new handling controls may benefit from discussing product options. We can clarify available formats to support informed product selection. Contact us today!