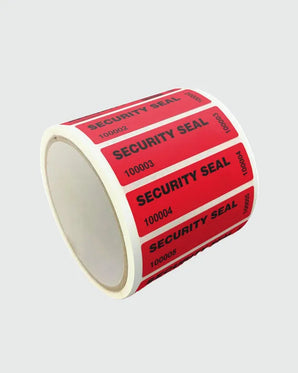

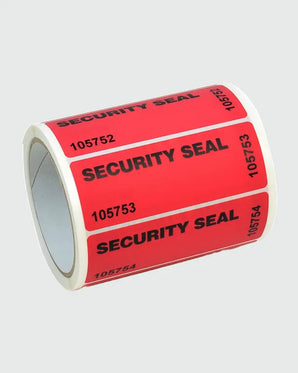

Packaging controls appear within many operational processes where items move between people or carriers. In these environments, the ability to assess whether packaging has been opened or interfered with supports inspection and decision-making during handover. The value of tamper-evident materials becomes most apparent where checks are routine, and transfers in responsibility occur.

Understanding how security tape is used and what evidence it provides helps organisations apply it appropriately within shipping and distribution workflows.

What are Tamper Tapes?

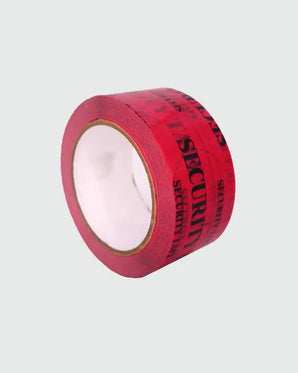

Security tape is used wherever packaging needs to show evidence of interference, if it happens, during storage or transit. It appears on cartons and wrapped pallets where inspection is part of an established process. The purpose is not to block access, but to make any unauthorised opening easy to identify during checks.

In logistics, distribution, and fulfilment operations, packaging integrity supports accountability. When parcels move between sites, signs of interference help teams confirm whether inappropriate handling has occurred since dispatch. This is where tamper-evident tape has a defined operational use.

How is it Different from Standard Packing Tape?

Standard packing tape is designed to seal cartons and keep packaging closed. It prioritises adhesion and strength but does not provide evidence if it has been lifted and reapplied. Once removed, many standard tapes can be pressed back into place with little sign of disturbance.

Tamper tape is manufactured to leave a clear mark, message, or physical change if removal is attempted. In shipping, this difference can affect how packaging checks are carried out at handover points.

What Physical Evidence Appears When Tape is Removed?

Removal creates an obvious change to the tape, the surface beneath it, or both when it is applied. Common formats include films that fragment or printed layers that reveal a message once lifted.

This supports inspection by giving staff a consistent reference for what an intact seal should look like. Once altered, the tape cannot be restored to its original state. The information provided by the tape supports decision-making during receipt checks.

Why Does Packaging Integrity Matter During Transit?

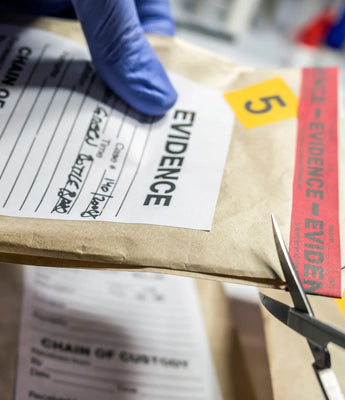

During parcel movement, items pass through multiple handling stages. Packaging that shows no signs of interference gives whoever is receiving the package confidence that the contents match dispatch records.

For parcels and shipments, tamper tape supports this process by making any opening attempt clear during inspection. In courier networks and internal distribution routes, this helps identify where handling issues may have occurred without assigning automatic fault.

How Does it Reduce Opportunity for Theft?

The tape does not stop access and does not secure contents. Its function is to discourage unauthorised opening by making interference obvious.

Where inspection is part of the process, the presence of the tape increases the likelihood that interference will be detected. This can reduce casual access during transit because altered packaging is easier to identify and escalate for review.

What are the Practical Benefits for Packaged Goods?

Benefits of tamper-evident tape for packaging relate to process control without claiming protection. Packaged goods sealed with tamper tape support clearer inspection outcomes at delivery points.

Key operational benefits include:

- Easier identification of opened cartons

- Faster inspection during goods-in checks

- Clearer audit records where discrepancies arise

These benefits only apply when inspection steps are defined and followed consistently.

How is Tamper Tape Used Within Supply Chains?

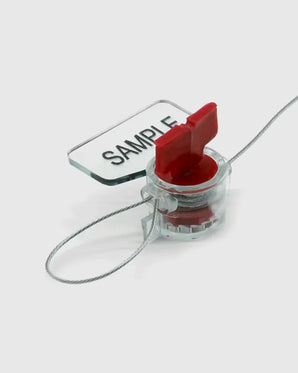

Within supply chains, this tape appears at transfer points where responsibility changes. This includes outbound dispatch or internal warehouse transfers.

Applied correctly, the tape provides a reference point for checking whether packaging has been opened between locations. It supports chain of custody records by linking packaging condition to specific handover stages.

What Installation Factors Affect Performance?

Installation guidance for tamper tape focuses on surface preparation and application method. Tape should be applied to clean, dry packaging surfaces to ensure predictable adhesion and removal.

Application pressure and placement across carton seams influence how well the tape performs during handling. Incorrect application can reduce the quality of the evidence shown if it’s removed.

How Does it Compare with Other Methods?

Comparing this tape with regular packing tape highlights functional differences. Regular tape seals packaging together but provides limited information once removed.

The choice between tape types should follow packaging processes and inspection needs. Substituting one for the other without process alignment can create false assumptions during checks.

Options for custom tamper tape allow organisations to specify print or messaging. Custom printing can support internal identification and make it easier to recognise during inspection. Available options include branded text.

What Compliance Considerations Apply to Tamper Tape?

In the UK, tamper-evident materials may be used within workflows governed by specific legal or contractual frameworks.

In logistics and transport, this can include obligations under the Supply Chain Security provisions referenced in ISO 28000, where evidence of interference supports inspection and incident review. In warehousing and distribution, tamper tape may be used within procedures shaped by ISO 9001 quality management systems, where packaging condition is included in documented checks.

In regulated environments such as healthcare or utilities, tamper-evident tape can support procedures aligned with MHRA guidance or NHS handling protocols. Although, the tape itself does not create compliance and does not certify adherence to any standard.

Responsibility for meeting regulatory or contractual obligations stays with the organisation managing the process.

When Should Packaging Controls be Reviewed?

This tape should be reviewed when handling routes are updated. Inspection outcomes can highlight whether current sealing methods provide enough information during checks.

Organisations assessing packaging controls may benefit from discussing product options and application methods. We can help clarify the available tamper tape formats and support you with an informed selection.

The Best Place to Source Your Tamper Tape

Sourcing this tape with us focuses on product specification and availability without defaulting to generic retail supply. As a manufacturer and supplier, we provide tamper tape designed for defined packaging and inspection applications.

Specification discussions can cover adhesive behaviour and surface compatibility. This helps organisations avoid changes in material performance that could affect inspection outcomes.

Supplying the tape to specification, we can inform you on lead times and help you consider how to apply it. Contact us for your tamper-evident tape today.