Seal Printing

Customisation

We can supply seals with custom print options such as barcoding, sequential numbering or company name/logos. We have in-house printing machinery that provides our customers with the lowest prices and quickest lead times on their security seals.

We utilise the latest technology and machinery to supply tamper evident seals for every level of security and across a wide range of industries. Our quality control and dedication to our customers means that we are committed to the achieving the highest independent standards, referring to the standard requirements of ISO-9001:2008 quality management systems for our processes.

Seal Customisation

As a UK seal printer, we understand that seal customisation is a necessity for many of our customers. Our custom printing allows our customers to have bespoke numbering, text and logos on their seal tags.

Print options

We utilise the latest technology and machinery to supply tamper evident

seals for every level of security and across a wide range of industries.

Our quality control and dedication to our customers means that we are committed to the achieving the highest independent standards, referring

to the standard requirements of ISO-9001:2008 quality management

systems for our processes.

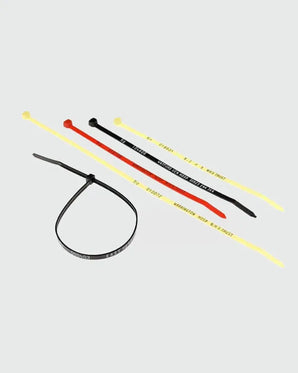

Why would I need plain seals?

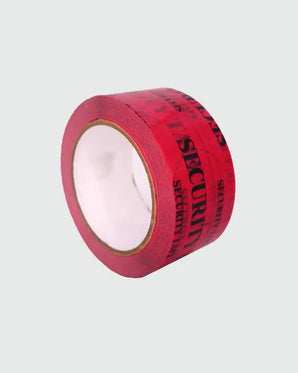

Unlike printed seals, which may include logos, serial numbers, or other custom markings, non-printed seals are typically plain but still designed to show clear signs of tampering, such as breaking, stretching, or leaving residue when removed.

Some customers also tend to overlay their own printed labels on their seals with specific data or details on them.

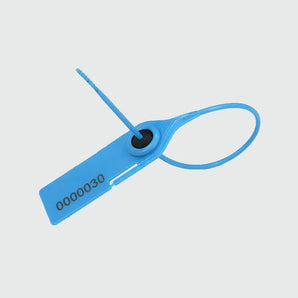

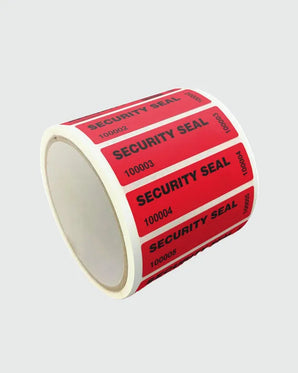

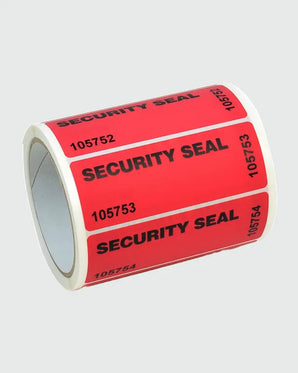

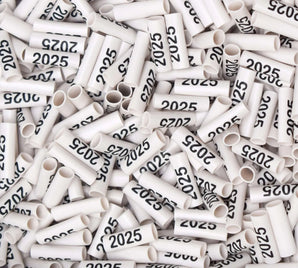

What are stock numbered seals?

Stock numbered security seals are the most common choice as they provide a numbering system to your security process but we can deliver them quicker from the stock we currently hold.

Their unique sequential numbering enhances tracking, accountability, and security. As each seal has a uniquely printed number on it, this allows precise tracking of who applied the seal, when, and where.

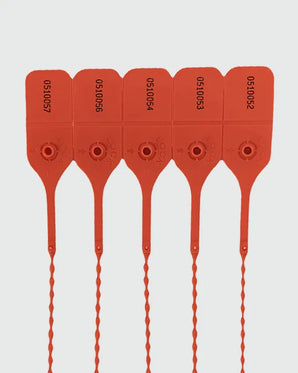

What are custom printed seals?

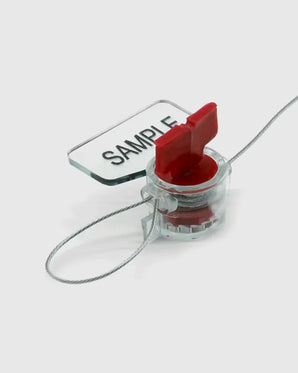

Custom printed security seals are tamper-evident seals that are personalised with specific text, logos, serial numbers, barcodes, or other unique markings tailored to your company needs. Unlike non-printed seals (plain with no markings) or standard numbered seals (with generic serial numbers), custom printed seals are designed to provide enhanced security, branding, and traceability for specific applications.

Custom printed seals allow for a more bespoke security seal system as unique serial numbers, barcodes, or QR codes enable precise tracking and verification, reducing the risk of seal replacement or fraud.

How do you custom print your seals?

We have multiple methods of seal printing which include laser printing, inkjet printing and hot foil embossing.

Hot foil stamping is a printing method used to apply metallic or colored foil onto security seals, creating durable and visually distinct markings. This process also has an embossing element to it, should the foil somewhat fade.

Inkjet printing is a digital printing method that propels tiny droplets of ink onto the seal’s surface. Inkjet printing is valued for its versatility, cost-effectiveness, and ability to produce custom designs, particularly for adhesive labels or flexible materials. It is a non-contact process, making it suitable for a variety of seal types and applications, though it may be less durable than other methods like laser printing or hot foil stamping.

Laser printing is the most effective form of printing and produces sharp, high-resolution text, serial numbers, barcodes, or logos, ensuring readability even for small or intricate designs.

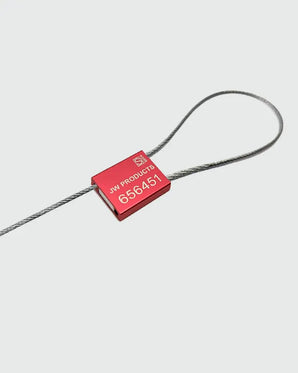

What is the turnaround for custom printed seals?

Our custom printed delivery times vary depending on the seal you require and the production schedule at the time of your order.

Typically, you can expect to receive plastic seals within 5-7 days. Metal barrier seals may take up to 10 days for delivery of custom printed seals.

Product News

Learn about any new product releases and developments

JW Products Upgrade Machinery for Printed Security Seals

JW Products have improved their in-house printing capability with the introduction of new machinery that will provide customers with improved...

Important update from JW Products

We are currently facing a life-changing situation and we want you to know that our customers, our employees and our...

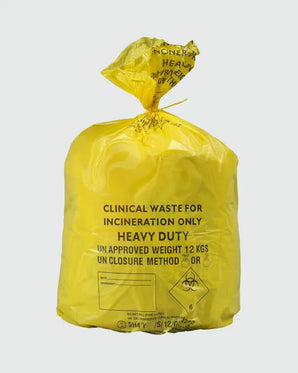

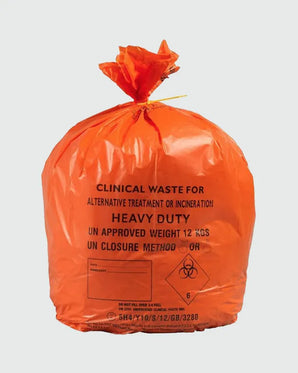

Clinical Waste Sacks Now Available!

JW Products manufacture security seals and clinical waste ties from our purpose built factory in Haydock, close to the Merseyside...