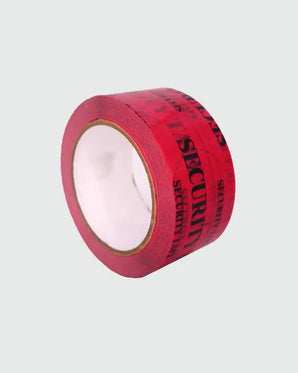

When a €41,000 shipment of OLED panels arrived in Felixstowe with a pristine box but half the contents missing, the carrier’s first instinct was to blame “factory stuffing error.” Forensic close-ups told a different story: a ghosted “OPENED” message clinging to the cardboard like digital DNA. The culprit? A tamper-evident residue label that left 100 % of its message behind when peeled.

Welcome to the era of residue-transfer security labels—the unsung heroes that turn every tampering attempt into undeniable courtroom evidence.

What Makes Residue Labels Different?

Unlike VOID-pattern films that fracture within the label, residue labels use a split-release adhesive: the top PET layer peels cleanly for inspection, while a high-tack underlayer stays glued to the substrate forever. Attempt to lift the label and the coloured message transfers irreversibly.

| Layer | Function | Typical Material |

|---|---|---|

| Face film | Printable, peelable | 50 µm matte PET |

| Message ink | Hidden until activated | UV-fluorescent red |

| Transfer adhesive | Stays on box | 35 g/m² acrylic |

| Release liner | Removed at application | Siliconised glassine |

Real-World Residue Forensics: Three Cases

1. Pharma Carton Swap – €1.2 M Recall Averted

A German CDMO shipped 8,000 vaccine cartons to Heathrow. One pallet showed a faint “OPENED” shadow under warehouse LED. Residue analysis under 365 nm UV revealed a perfect 1:1 transfer—no solvent wipe could erase it. The swap was traced to a rogue consolidation agent; recall limited to 400 units.

2. E-Commerce Return Fraud – 34 % Drop in Abuse

UK retailer ASOS applied 50 × 25 mm residue labels to shoebox lids. Returns with partial message transfer triggered automatic rejection. Fraudulent “worn once” claims fell from 2.8 % to 1.8 % in Q3 2025.

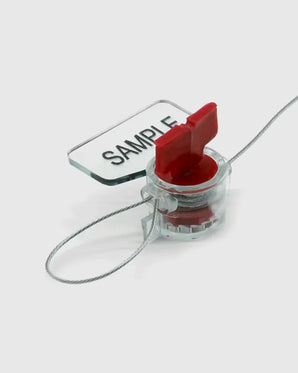

3. Aircraft Spare Tamper – FAA Audit Pass

A Boeing 737 APU arrived with a residue “SEAL BROKEN” on the crate. The label’s unique adhesive fingerprint (measured via FTIR spectroscopy) matched the OEM spec, proving the breach happened post-certification. Supplier faced a €280 k penalty.

Choosing the Right Residue Grade

| Grade | Transfer % | Substrate | Best For |

|---|---|---|---|

| Light | 60–70 % | Coated paper | Low-value CPG |

| Standard | 85–95 % | Corrugated, plastic | General logistics |

| Aggressive | 100 % | Wood, metal | High-security crates |

| Freezer | 100 % @ –30 °C | Frozen cartons | Cold chain |

Pro Tip: Test dwell time. Aggressive grades need 24 hours to reach full transfer strength.

Application Hacks from the Warehouse Floor

- Surface prep – Wipe dust with 70 % IPA; oils kill transfer.

- Pressure matters – Use a 2 kg roller for 3 seconds.

- Corner tabs – Add a 5 mm non-adhesive tab for clean inspection peel.

- Dual-message – Print “OK” on face, “OPENED” in residue for zero ambiguity.

Your 5-Step Residue Label Rollout

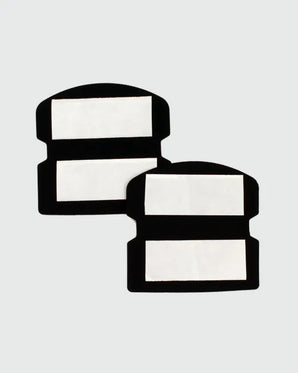

- Audit substrates – Send samples to lab for transfer testing.

- Pilot 1,000 units – Track with photo logs at receipt.

- Train staff – 90-second video on roller technique.

- Integrate TMS – Auto-flag partial transfers in WMS.

- Measure monthly – Claims delta = your KPI.

Bottom Line

A residue label doesn’t prevent tampering—it prosecutes it. In an age of porch pirates, consolidation fraud, and six-figure recalls, that €0.09 sticker is the cheapest insurance you’ll ever buy.

Request samples of our residue labels