What is a spill kit and why are they important?

A spill kit, also known as a chemical spill cleanup kit or absorbent spill kit is an essential tool to assist with the decontamination, cleanup and disposal of waste in the event of a spill.

Spill kits are an assembly of various materials to aid the cleanup of a chemical leak or spill. A wide range of spill kits are available on the market depending on your business needs. We offer various kits for different chemical types and quantities for different use cases.

Effective spill control measures are essential for reducing the impact of a spill, including containment and proper cleanup procedures. Spill clean-up and remediation can be costly, but the sooner a spill is cleaned up the cheaper the overall cost. Spill kits allow you to contain and clean up a spill immediately preventing a larger, more costly issue where the Environment Agency could get involved.

Chemical spill kits also reassure employees, making sure they have a safe working environment. This is because they know that if needed, they can protect themselves and others at work if an accident were to occur.

If a spill isn’t correctly cleaned up, this can also lead to adverse environmental effects. These include:

- Risks to human health – Large spills can cause immediate dangers to people in the workplace and the local community. Inhaling fumes or coming into contact with the spill could cause serious injuries

- Bioaccumulation – Occurs when the body gradually accumulates certain chemicals in its tissues and fluids over time due to exposure. Such prolonged accumulation poses a risk of causing lasting harm to people or wildlife.

- Soil contamination – The spill could contaminate crops and plants creating risks to human health if these contaminated crops are consumed. Wildlife can also be put at risk because of habitat destruction.

- Pollution to water sources – Groundwater is used for crop irrigation and drinking water for people and animals. If water is consumed that is contaminated with chemicals from a spill it can be severely harmful to health depending on the chemical and concentrations.

- Damage to marine ecosystems – Once your spilled chemical reaches a water source it can quickly reach the ocean. It can then continue to harm wildlife with the effects becoming more widespread.

What are the different type of spill kits?

There are three main different types of spill kit which are all available in different sizes to suit the workplace risk requirement. Typically spill kit sizes range from simple 20 Litre grab bags to wheelie bins and lockers of 120, 240, 360, 400, 600, 800 and 1100 litres in size.

Places of work which typically require onsite spill kits are, as example, garages, hospitals, laboratories, breweries, manufacturing, and chemical facilities.

General maintenance spill kits is the most common spill kit and the absorbents are colour coded grey in accordance with BS 7959 part 3 and are suitable for use on water-based liquids, coolant, cutting fluid, oils, fuels, mild solvents, and hydrocarbons (oil and fuel).

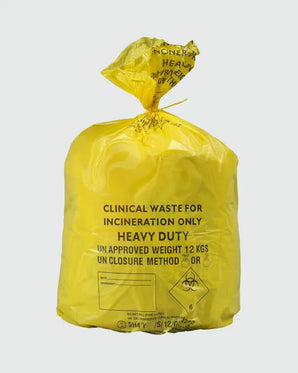

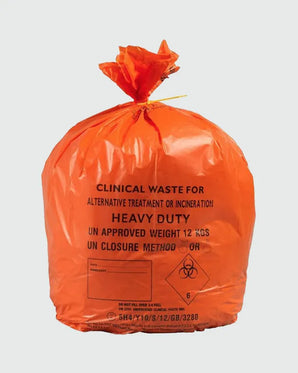

Chemical/Hazchem spill kits absorbents are colour coded yellow in accordance with BS 7959 part 3 and will absorb almost any liquid from water through to hazardous materials such as corrosive acids, solvents, and aggressive chemicals. These can include chemicals such as coolant, degreaser, paint, blood, bodily fluids, oils and fuels as well as mild acids, bases and water-based chemicals.

Oil selective spill kits kit absorbents are colour coded white and blue in accordance with BS7959 part 3 and are designed to repel water and only absorb oil and fuel hydrocarbons. The absorbent materials are also designed to float on water so more effective at cleaning up hydrocarbon spills.

Other options are also available for hazardous spills, such as petrol and diesel which are flammable, and biohazard risks including blood and other bodily fluids. For information on handling a chemical spill correctly, check with government health and safety legislation.

Laws & Requirements

In the UK, there are strict laws that protect land, water, air, wildlife and people from pollution. If you or your company is the cause of chemical pollution, then you could be committing a criminal offence. Pollution penalties may include fines, imprisonment, and expenses related to cleaning up, remediation, and addressing the damage caused by a spill.

In the UK, while there isn't a single dedicated "spill kit regulation", businesses are required to have appropriate spill kits readily available based on the substances they handle, as per guidance from the Environment Agency, which means they must be suitable for the potential pollutants on site and readily accessible where needed; failure to do so can lead to prosecution if a spill occurs that could have been contained by a spill kit.

Key points about spill kit requirements in the UK:

- British Standard (BS 7959): The UK generally references BS 7959 standard for spill control materials, which outlines requirements for sorbency levels of absorbent materials used in spill kits.

- Identifying potential spills: Businesses must assess the types of liquids they handle to determine the appropriate spill kit needed, including whether it should be designed for oil, chemicals, or a general purpose.

- Spill kit contents: Depending on the substances involved, spill kits should include absorbent pads, socks, containment barriers, appropriate gloves, safety goggles, and disposal bags.

- Placement and accessibility: Spill kits should be located near where potential spills could occur and be readily accessible to employees.

COSSH Regulation

The UK regulation is guided under COSHH, which stands for 'Control of Substances Hazardous to Health'. COSHH is a set of regulations put in place to protect workers from ill health when working with specific substances and materials. Breach of COSHH regulations by an employer or employee is a crime, punishable by an unlimited fine.

COSHH was introduced to control the exposure of a business’ employees to hazardous substances. A COSHH assessment concentrates on the hazards and risks from substances in a workplace and asks questions such as:

- Where is there potential for exposure to substances that might be hazardous to health?

- In what way are the substances harmful to health?

- What jobs or tasks lead to exposure?

- Are there any areas of concern?

The COSHH legislation has a number of step-by-step procedures and guidelines that need to be actioned in order to protect employees from ill health in the workplace. We have broken down these required methods below in order to highlight the steps employers must take in order to protect their workers’ health.

- Identify health hazards

- Conduct a risk assessment

- Provide control measures

- Prevent or control risks

- Ensure control measures are actioned and measured

- Provide information and training for employees

- Offer health surveillance and monitoring methods

- Be prepared for emergencies

You can read more about COSHH regulation here. You should also familiarise yourself with guidance note for the Control of Pollution (Oil Storage) (England) Regulations 2001 under DEFRA.

Mitigation and Safety Control

You need to ensure a spill kit is positioned in a prime position, where everyone knows exactly where to find it and close to the main risk so it can be grabbed quickly in an emergency. This is vital because liquid can quickly spread, meaning immediate action is essential to contain and reduce the risk.

The equipment provided should be regularly checked to ensure it is fully stocked for such an emergency, with training given to those working in the area so they know how to handle a spill situation. Additionally, it is good practice to install signs and posters to provide a helpful reminder. The inspection and maintenance procedure should include:

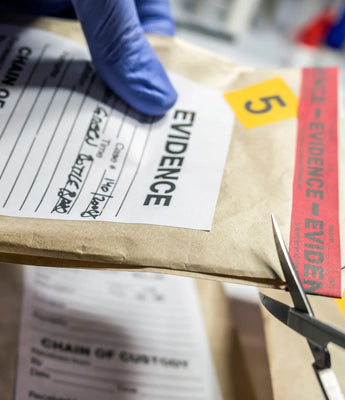

- Checking Inventory: Regularly verify that all necessary components are present, including absorbents, gloves, safety goggles, pads, booms, and disposal bags.

- Inspecting the Condition: Items such as absorbent materials should be checked for degradation, wear, or contamination. Any damaged or used materials should be replaced immediately.

- Expiration Dates: Some spill kit items, such as certain absorbents or chemical neutralizers, may have expiration dates. Ensure these products are replaced in a timely manner.

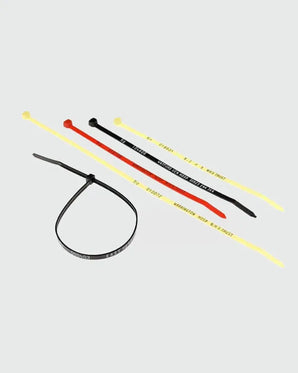

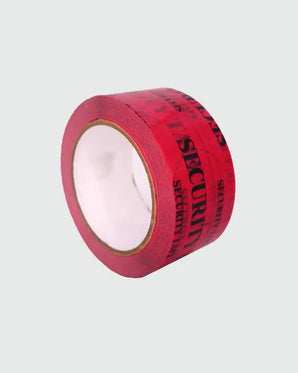

- Sealing and Labeling: Keep the spill kit sealed to protect the contents from environmental factors that could reduce their effectiveness. Properly labeling the kits with both contents and instructions for use will aid in emergency response.

Having a spill kit on-site is only part of the solution as workers need to be trained in how to use it effectively and safely. Training should include:

- Proper Use of Materials: Employees should be familiar with each item in the spill kit and its intended purpose—whether it’s absorbent pads, socks, or chemical neutralizers.

- Safety Procedures: Employees should know how to safely handle hazardous materials and manage a spill situation, including the appropriate protective gear to use and disposal methods.

- Emergency Response Plans: Spill kit users should be part of a broader emergency response plan, with clear communication channels for reporting incidents and getting assistance if needed.

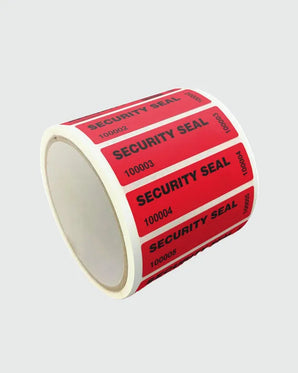

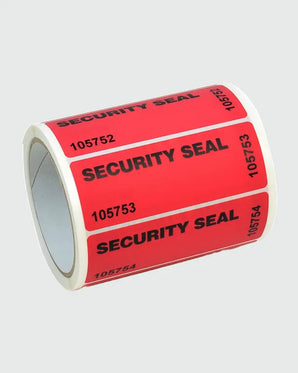

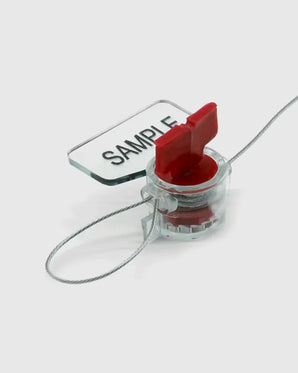

In addition, the spill kits should be regularly inspected to ensure they are properly replenished. Adding a seal to the spill kits will help simplify the inspection process. We have expanded on the benefits of including security seals as part of your spill kit inspection procedure to reduce risk and identify potential hazards quicker.

Effective safety control over spill kits involves more than just having the right tools on hand—it’s about ensuring proper placement, maintenance, training, and regulatory compliance. By following these best practices, companies can ensure that their spill kits are ready for immediate action in an emergency, safeguarding both employees and the environment.

Secure seals & audit tags

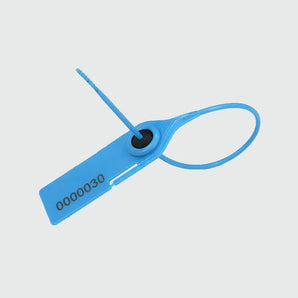

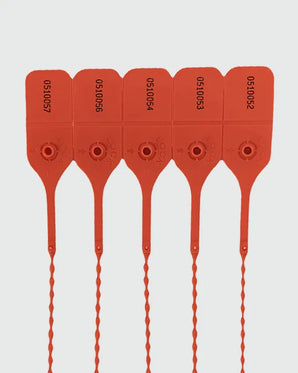

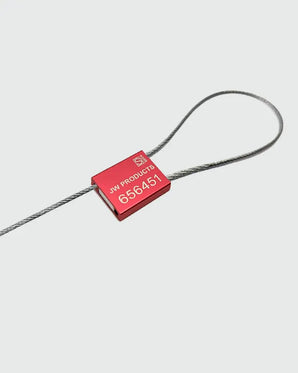

Security seals and audit tags readily identify when a spill kit has been accessed or used and help prevent unauthorised access. They act as a visual indicator that a spill kit or wheelie bin has been potentially tampered with or misused.

- Prevent personnel partly using absorbents and spill kit components, or stop wheelie bins being used as rubbish receptacles.

- Ensure all spill kit access is monitored and highly visible – simply break the tag to access the kit’s contents in the event of a spill.

- Security seals lock the wheelie bin lid to the wheelie bin body.

- Each security seal has a unique serial number for audit recording if required. They can also be printed with other text such as department names or emergency telephone numbers.

- Security seals can be bespoke made and designed to suit 240 litre and 120 litre wheelie bins.

Facilities are also required to regularly inspect and replenish their spill kits to ensure they meet safety regulations. If the seal is broken, it’s a clear indication that the kit needs to be checked to confirm that it still contains all of the necessary materials and that nothing has been removed or damaged.

Using security seals can also help to demonstrate strict compliance with the regulations discussed previously. If your facility undergoes an inspection, having security seals on your spill kits shows that you take spill response seriously and that the kits are maintained in a secure and reliable state.

Security seals are a small but highly effective tool for enhancing the safety, compliance, and functionality of spill kits. By preventing tampering, ensuring proper maintenance, and demonstrating adherence to safety regulations, these seals contribute to a more secure and efficient spill response system. As part of a comprehensive spill preparedness plan, security seals provide a clear signal that your facility is committed to maintaining a safe environment for workers and the surrounding community.